“AI-based condition monitoring for PdM approach solution will add value to the ALPSD-1000 PSD system design and positively affect its competitiveness in the market. We support the doctoral thesis of one of our employees in accordance with the scope of the project.

For this reason, our studies and analysis of obtained results will add value to the literature with scientific research publications.”

The high availability of PSD systems are key to ensure the safety of public transportation. While having availability in mind, transportation service operators must also manage the maintenance and Life Cycle Costs of PSD systems.

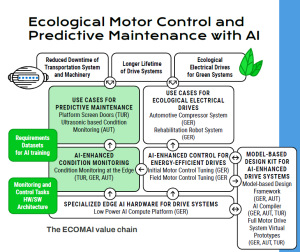

In this use case, an Al-enhanced data-driven predictive maintenance approach for condition monitoring is developed. lt responds also to the wider ecological goals of the ECOMAI project to save energy, reduce maintenance costs and reduce maintenance waste in general.

The ECOMAI Value Chain

The Use Case for Platform Screen Door Systmes provided by consortiums partner Albayrak is focused on Predictive Maintenance and AI-enhanced Condition Monitoring

Commercial Viewpoint

Al-enhanced predictive maintenance methods have not been implemented so far in PSD systems. The innovation is to use Al-enhanced predictive maintenance to increase the availability of PSD systems while reducing maintenance activities. By using predictive maintenance enhanced with artificial intelligence, intensive preventive maintenance (PM) tasks can be reduced while achieving high availability of the PSD system, and optimum maintenance tasks can be performed using minimum manpower with energy savings, reduced cost and reduced material waste. Intensive preventive maintenance and failure-free material changes can be a factor in increasing Life Cycle Cast (LCC).

The high availability of PSD systems are key to ensure the safety of public transportation. While having availability in mind, transportation service operators must also manage the maintenance and Life Cycle Costs of PSD systems.

In this use case, an Al-enhanced data-driven predictive maintenance approach for condition monitoring is developed. lt responds also to the wider ecological goals of the ECOMAI project to save energy, reduce maintenance costs and reduce maintenance waste in general.

MARKET NEEDS ADDRESSED

• High availability of functionality and no interruption of passenger transportation services by PSD

• Reducing the maintenance cost of the PSD system.

• Reducing the Life Cycle Cost for the PSD system.

GOAL: A UNIQUE PSD SYSTEM DESIGN

Al-enhanced condition monitoring and data-driven predictive maintenance approach, to increase the availability up to 99,9% and competitiveness of the ALPSD-1000 PSD

system produced by Albayrak.

Consortium Partner ALBAYRAK MAKİNE ESKİŞEHİR

Albayrak designs and manufactures Platform Screen Door systems (PSD) for the railway industry. The company is the first and the only PSD manufacturer in Turkey. lt has completed various projects under brand name „ALDOOR“ in Turkey and international market. The company has SIL (Safety lntegrity Level) certificate for ALPSD-1000 PSD systems.