ECOMAI

Ecological Motor Control and

Predictive Maintenance with AI

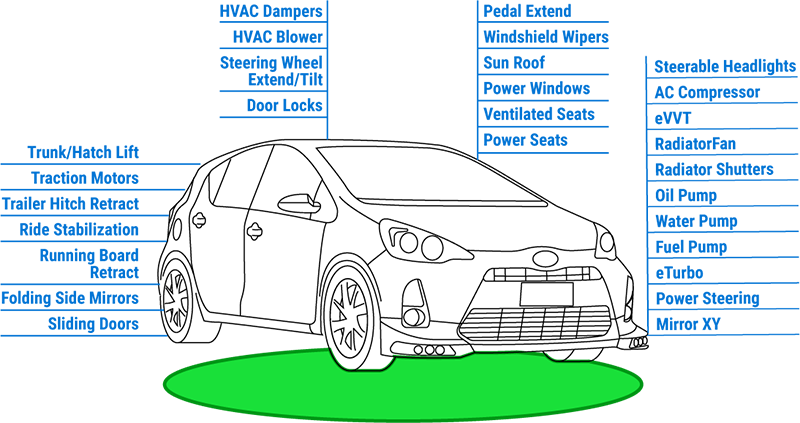

Electric motors are everywhere from laptop fans and dishwashers to industrial machinery, robots, public transport and more. A modern car can alone contain about 40 motors for various functions. But these valuable uses come at a cost. It has been calculated that electric motors account for 40% of worldwide power consumption and 20% of CO2 emissions*.

Mission

To address these issues, the ECOMAI project is developing technologies

-

to enhance electric motor drive systems with an embedded AI system running on a specialised AI hardware platform

-

to optimise the efficiency and lifetime of electric motors, thereby reducing energy consumption and enabling development of more ‘ecological’ systems

-

to lead to market opportunities for applications in numerous sectors including automotive, medical and transportation.

Goals

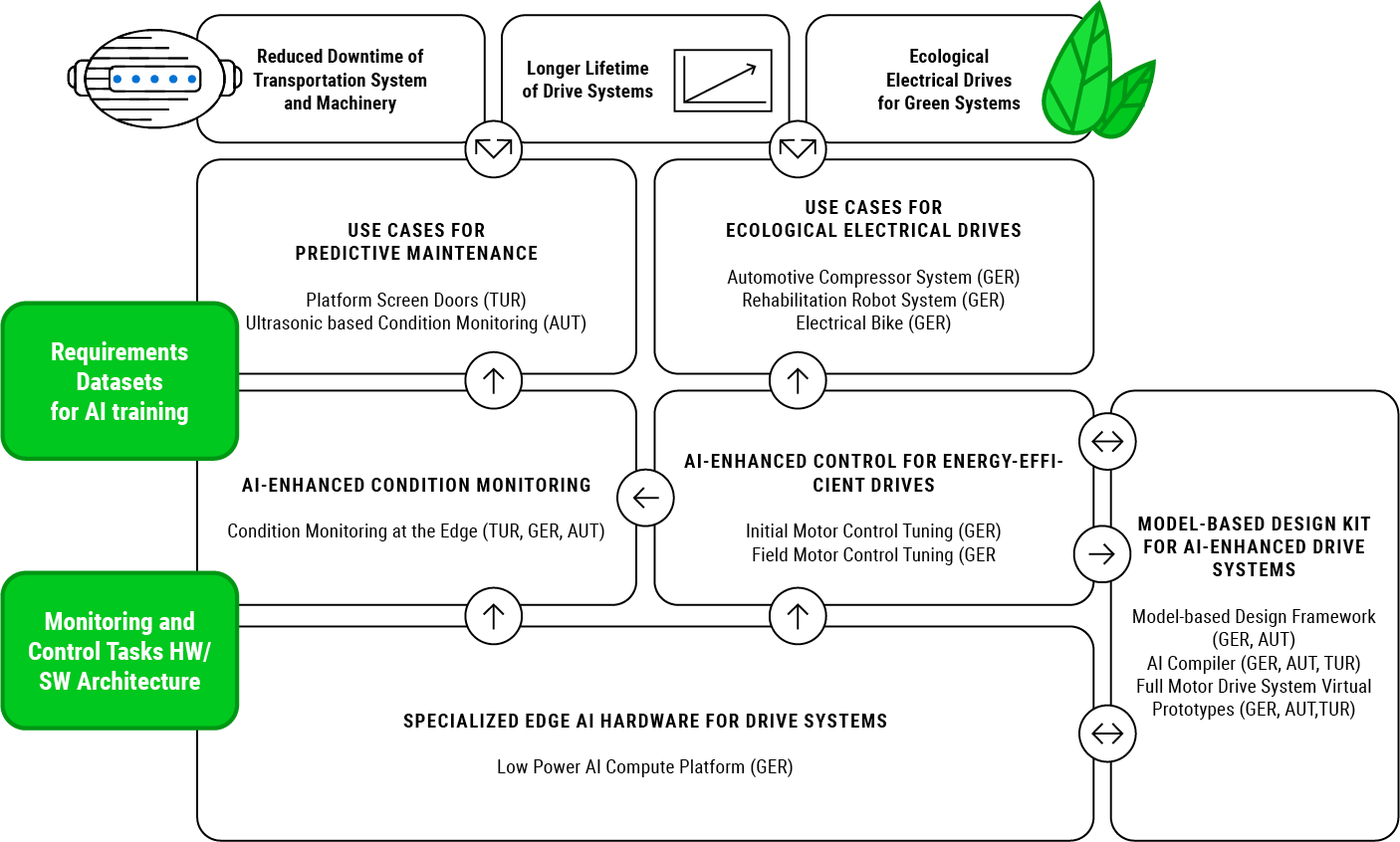

Technical Goals

This platform will provide both cost-efficient AI functionality and explore advanced accelerator and approximate computing principles. Furthermore, ECOMAI will deliver an innovative Model-based Design and Automation Framework: a full development toolkit that combines model-based design and an AI compiler for the specialised hardware platform along with a full system modelling and simulation environment. This will make ECOMAI’s technologies easily accessible, particularly for SMEs.

Develop a Edge AI Solution to be integrated into Motor drive systems consisting of:

- Specialized AI hardware platform

- Development kit with AI compiler, model-based design and simulation environment

- AI Applications for Predictive Maintenance and Energy-efficient Control to execute on the hardware.

Expected impact

The ECOMAI project offers a basis for Europe to establish a leading role in AI-enhanced electrical motor drive technology – from hardware to applications – through solutions that support the green and digital transitions.

- Contribute to the objectives of the European Green Deal by enabling more ‘ecological’ solutions now and paving the way to further energy saving options in the future

- Respond to a rapidly growing market for AI chips, motor control chips and motors in general (growth rate globally of 8% by 2025 for Electric Motors)

Key Application Areas

Digital Industry

Mobility

Quality, Reliability, Safety and Cybersecurity

Essential Capabilities

Architecture and Design: Methods and Tools

Artificial Intelligence, Edge Computing and Advanced Control

Components, Modules and Systems Integration

Technology Value Chain and Use Cases

‘Ecological’ use cases:

- An automotive compressor system demonstrating the potential of AI to deliver better control performance.

- An electrical bike testbench for intelligent sensorless electric bike traction applications, incorporating an AI-based torque control algorithm.

- A test environment for a robotic rehabilitation system for mobility impaired people, exploring, amongst other functionality, capabilities for neuro-feedback.

Condition monitoring and predictive maintenance:

- A railway Platform Screen Door (PSD) system, including AI enhanced PdM algorithms and the TinyML edge device developed by ECOMAI to prolong operational availability.

- An ultrasonic traducer, using AI to understand which changes of the driving signal will be the result of certain alterations in a structure or volume when excited by the ultrasound: a motor, a battery or another complex medium for ultrasonic-based condition monitoring.

News

Virtual Prototyping and explore Performance Achievements

“Towards Rapid Exploration of Heterogeneous TinyML Systems using Virtual Platforms and TVM’s UMA”

Scientific Paper by TU Munich

AI for Motor Control – Master Thesis University of Ilmenau

We are very pleased to present the latest research paper in our ECOMAI ecosystem from the University of Ilmenau

Presenting the Ecological Approach of AI and Predictive Maintenance

ECOMAI at the 13th Arab-Austrian Economic Forum in Vienna on the 27th of November 2023

![BMBF_CMYK_Gef_M [Konvertiert]](https://ecomai.eu/wp-content/uploads/2022/11/BMBF_gefoerdert_2017_en.jpg)